In today’s world of rapid urbanization and climate change, the design and construction industry is under immense pressure to move towards sustainable practices. Architects, interior designers, and businesses are seeking innovative materials that not only perform well but also reduce environmental impact. One such breakthrough solution is the recycled plastic panel—a versatile, durable, and eco-conscious surface material that is transforming the future of design.

At Minus Degre, we have pioneered this movement in India with our Eco-Panel: a 100% recycled and 100% recyclable surface material made from post-consumer and post-industrial plastic waste.

🌍 The Need for Sustainable Surface Materials

India generates over 3.4 million tonnes of plastic waste annually, of which nearly 60% is not recycled (Plastic for change). Traditional surface materials like virgin plastic, marble, MDF, or laminates consume natural resources, add to carbon emissions, and are often non-recyclable.

Eco-Panels offer a circular solution—diverting plastic waste from landfills and giving it a new life as a high-quality, long-lasting surface material.

💡 Performance That Matches Modern Needs

Recycled plastic panels are not just “green alternatives”—they are engineered for performance:

- Durability: Resistant to water, termites, and rotting, unlike wood or MDF.

- Strength: Sturdy enough for heavy-duty use in furniture, cladding, and countertops.

- Low Maintenance: Easy to clean, stain-resistant, and highly resilient to daily wear and tear.

- Design Flexibility: Available in stunning patterns and colors naturally created from recycled waste.

📊 Eco-Panel vs Conventional Materials

| MDF | Moderate | Needs sealing | Low | Not recyclable | Medium |

| Laminate | Scratch-prone | Low | Low | Not recyclable | Low |

| Marble | High | Moderate | Low (mined resource) | Not recyclable | High |

| High (water & termite proof) | Very Low | High (100% recycled) | 100% recyclable | Medium |

This table helps designers, architects, and buyers compare performance, cost, and sustainability directly.

🏭 How Eco-Panels Are Made

Eco-Panels are crafted by sorting, cleaning, and compressing post-consumer and industrial plastic waste at controlled high temperatures. This process locks in strength and creates unique, natural patterns without additional dyes or chemicals.

By using a circular production model, Minus Degre ensures that every panel contributes to waste reduction and a sustainable economy.

🏢 Real-World Applications of Eco-Panels

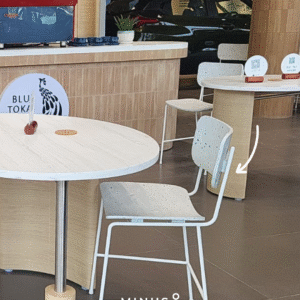

Minus Degre’s Eco-Panel has already found its way into leading projects across India and abroad:

Tata EV Stores

Eco-Panels were used as wall cladding and counters, reducing virgin material use by 30% and providing a sleek, durable finish for retail spaces.

Adidas Flagship Stores

Sustainable display furniture and panels were created from 100% recycled plastic, aligning with Adidas’s global sustainability goals.

Aldo Retail Stores

Shop interiors were transformed using Eco-Panels for counters and wall cladding, offering an aesthetic, eco-conscious retail environment.

CSR & Events

Eco-Panels are also used for trophies, medals, and souvenirs, helping brands and organizations meet CSR and sustainability goals.

Urban Infrastructure

Park benches, dustbins, and public furniture crafted from Eco-Panels are durable, weather-resistant, and maintenance-free.

🌱 Eco-Benefits That Make a Difference

Choosing Eco-Panels is not just a design decision—it’s an environmental action.

- Waste Reduction: Each panel diverts kilograms of plastic waste from landfills.

- Circular Economy: Panels are recyclable at the end of their lifecycle, ensuring zero waste.

- Low Carbon Footprint: Manufacturing uses significantly less energy compared to virgin plastic or natural stone.

- Sustainable Branding: Using Eco-Panels in retail stores, offices, or furniture demonstrates commitment to sustainability.

FAQ: Common Questions About Eco-Panels

Q: Can Eco-Panels be used outdoors?

Yes, they are weather-resistant and suitable for park benches, outdoor furniture, and facades.

Q: How are the colors created?

The natural mix of recycled plastics forms unique marbled patterns without artificial dyes.

Q: What is the cost per square foot?

Pricing varies by thickness and finish, starting from ₹Rs.40 per sq. ft. Contact us for a custom quote.

🚀 Why Eco-Panels Are the Future of Sustainable Design

The design industry is shifting towards materials that combine performance, aesthetics, and responsibility. Eco-Panels are more than just recycled products—they are a symbol of innovation, conscious living, and future-ready design.

At Minus Degre, our mission is to change the perception of plastic waste by turning it into valuable, premium-quality materials. By choosing Eco-Panels, architects, businesses, and communities can take a bold step towards a greener and smarter future.

📞 Take Action: Make Your Project Sustainable Today

Ready to build your next project with Eco-Panels?

- Request a Free Sample Kit

- Download Our Product Catalog

- Contact Us to discuss your custom project